1. Solid Wood

Old kitchen cabinets either the base, the wall/overhead(cupboard) were mostly of solid wood in varnish or wood stain finish which up to this date still exist and not yet totally phased out.

|

| image from lowes.com |

Downside of these wooden materials are not "water proof" and still subject to warping, plus to be mindful of termite/insect infestation when not properly treated or coated with varnish, or paints.

2. Plywood (ordinary, marine)

From solid wood came a new material such as ordinary plywood as an option for cabinets, including "lawanit" both of the same size of 4' x 8'.

With the advent of ordinary plywood, you also have your marine plywood which is water resistant than the ordinary which is suitable to extreme wet conditions like the base cabinet in kitchens.

Just don't be confused on terms of being "water resistant" vs "water proof".

Same as wood, plywood can still be infested with termite/insects in the long run when not properly treated with chmicals/ maintained and coated with secondary protection like paints.

Trivia: Marine Plywood process (from YT by How it's made)

If you like high gloss finish for your cabinets then you may apply "Duco" finish which may be costly but somehow adds more protective coating to your plywood surfaces.

Sample Duco Finish (high gloss)

|

| image from myboysen.com |

psssst Boysen "baka naman"...

Particle board and MDF-best used as substrates for laminates but not directly used as cabinets without any protective layer.

These two came out later on but not highly known or didn't get that much public attention, that when Formica came out it was not yet focused on furniture but on circuit boards, until it realizes that the particle board is a good substrate for its laminate and came up with countertops and some laminated furniture parts.

3. Modular Cabinets

a. Melamine and HPL

It came out as early in the 30's to solve kitchen problems on few areas for storage in addition to the introduction of continuous countertop.

Now being adapted not only in small residential units but including high rise condominiums and offices with small pantry or canteen that requires some storage areas.

Modular in the sense that you can combine two typical cabinets to form larger modules, in other words it's like a lego block that you can assemble, interchange and modify to conform with client's needs.

These new cabinets comes in Melamine (Low Presure Laminates) and HPL (High Pressure Laminates), remember that laminates are thin sheets of paper mixed with resin applied with either high or low pressure before being glued to a particular substrate.

Preferably go for HPL with marine plywood substrate for your "base" cabinets that is more exposed to moisture and Melamine (LPL) for your overheads. or if you have the budget simply have it all in HPL finish.

Sample HPL kitchen cabinets

|

| image from decocity.com.ph |

|

| image from easywoodproducts.com |

For DIY enthusiasts, you may explore also phenolic laminates or Formica compact product mentioned here.

b. Aluminum

Powder coated metal cabinet system combined with glass framed doors, now comes with a wood grain finish making it look like wood, though not genuine when you touch up close like your original wood stained cabinets.

Process for wood grain aluminum undergoes powder coating with added decorative film wrapped around through sublimation process.

|

| image from gabrian.com |

How wood grain is achieved in aluminum (YT from DecoralSystem)

This is more preferred due to its water and pest resistant capabilities with low maintenance compared to solid wood or plywood but way more expensive than the two.

Some reviews of aluminum cabinet owners shares their experience that overtime:

- cabinet doors hinges may loosen up causing it to sag or droop

- too noisy compared to wooden cabinets

- some portions of powder coat starts to peel off (depends on supplier)

- even if coated still prone to scratches if not extra careful

- dents if you accidentally drop hard objects

Best to check first from your nearest supplier and check if they are using "soft closing hinges" for its cabinet doors, check if sidings or edges are not that sharp to avoid unnecessary cuts and the overall quality of their craft if it meet your standards.

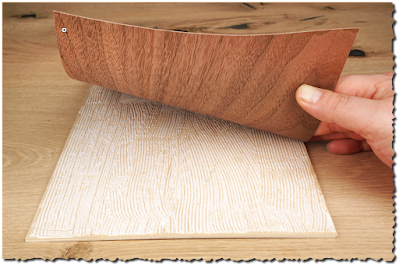

c. Veneer

Thin cut of "real" wood that would be glued to a substrate which may be similar to your LPL or HPL finish except that these two laminates are made from piece of paper and resins.

Thus it is more expensive since it is all natural compared to artificial made laminates.

|

| image from feinschnitt-kreativ.de |

Depending on client's need, veneer finish can be requested instead of a laminate finish to have a genuine wood appearance but is more prone to scratches unlike from laminates having an additional protective layer which is more durable.

d. PVC cabinets (Not yet commercially adapted in the Philippines, more on DIY)

PVC as "polyvinyl chloride" have wide variety of applications not only limited to pipes, doors, walls, ceilings, flooring (vinyl), but now also caters cabinets for your kitchens.

Do take note that pvc cabinets have two options:

- hollow pvc boards which are lighter and cheaper

- foam pvc boards which are more durable but more expensive than hollow pvc

Almost same features as aluminum of being anti termite and rust free since its not made of wood, it is also easier to clean and less maintenance unlike wood that needs repaints.

So far the following pvc boards brands commercially available in the Philippines includes:

- Primoboard-primoboard.com.ph

- Versaboard-allhome.com.ph

- Versaply-steelcaretrading.com

Sample PVC kitchen cabinets:

|

| image from primoboard.com.ph |

|

| image from designingidea.com |

Why choose PVC cabinets?

|

| image from https://www.pvcinnovations.com/ |

To decide which one you should choose from mentioned finishes for your kitchen, again comes down to:

- your budget

- availability near your area of location

- your preference if natural look finish or artificial that simulates wood finish

- anti termite and water resistant

- scratch proof and less maintenance

- the amount of weight capacity of overhead cabinets with less sagging

If you can find a supplier with its own manufacturing plant would be a plus factor at least somehow you are assured of quality control from cutting of frames to application of powder coat for aluminum cabinets, cutting of boards and application of laminates for HPL cabinets and so on, the better.

Final say, you can combine and experiment with different materials like aluminum carcass and use laminated door cabinets, or angle bar framing and solid wood door covers, as you are not limited to stick with one main material but can come up with different available materials (Hardiflex for backing and sidings maybe?).

Disclaimer: This is not a paid promotion of any brands mentioned in this post but for sample reference only to get some idea.