Cement Sand and Gravel

These 3 when mixed with water and hardens becomes your concrete as finished product. Your cement will act as a binding agent to your aggregates (sand, gravel, stone etc) with the help of water which go into chemical process called "hydration".

Ways of mixing concrete:

- Job Mix-done on site (for small scale projects)

- Batch Plant-from batching plants ready mix for delivery (for big projects)

Density

In general the "density" of cement in a cubic meter (1m³) is approximately 1440kg/m³. This value is your main reference on how number of bags of cement were derived in your estimates.

The Cube (1 cubic meter = 1m x 1m x 1m)

Sample cubic meter (1m x 1m x 1m), imagine this cube as a container box filled with cement in its powder form which has a total mass of 1440 kilograms.

Bag of Cement (40kg, 50kg)

Commercially available in our market and commonly used is a 40kg bag of cement, therefore if you divide the density earlier of 1440kg to 40kg you have 36 bags of cement that can fit your cube or per cubic meter.

Remember this number 36 bags per cu. m, it will be handy even if you are in the field and need not memorize any table for estimating your needed bags of cement.

Volume

To convert this 40kg to a cubic meter (volume), simply divide 40kg/1440kg gives you 0.02777m³. Imagine your cube to be composed of 36 bags but in a smaller cube/box form as shown below.

|

| 36 bags/box of 40kgs cement per cu. m |

Gauge/Measuring Box

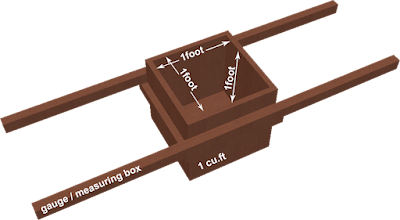

The old school method to get the proper mix ratio for our CSG (cement,sand,gravel) uses a gauge/ measuring box made out of wood with a dimension of 1ft x 1ft x 1ft (30cm x 30cm x 30cm) equivalent to 1ft³ or a volume of 0.0283m³.

|

| measuring box |

So we are safe to say that 1 bag of 40kg cement can "fit" in to our measuring box since 0.02777m³. is lesser than 0.0283m³. of our "kahon".

A. CONCRETE MIX RATIO (C: S: G: per m³)

There are different ratio for designated house structure application, that is why a Structural Engineer/ project supervisor must be present during preparation and pouring of concrete to make sure that the proper mixing ratio is strictly followed to achieve the desired level of compressive strength.

Sample Table of Class mixture and compressive strengths and will vary on actual construction site depending on weather condition, material used, actual mixture etc.

|

| Table 01 concrete class mixture, application and quantity of CSG per m³ |

To understand how values of bags of cement were derived for each class was literally based on the mixing ratio of cement, sand, and gravel per cubic meter.

Class AA = 12 bags of Cement mixing ratio is 1: 1.5 : 3 when you divide this ratio by 3 you get the following:

0.3333: 0.5: 1

note:

- 3 is your gravel ratio in sample mix above, so use this as your divisor for the other ratios.

- or 36 bags divide with 12 bags you get 3 as your gravel ratio.

All expressed in cubic meter, now you have solved sand and gravel volumes, and you may wonder about cement in 0.3333 m³, divide this with the volume of cement earlier of 0.02777m³ and you get 12 bags as result.

To make computation much easier just multiply 0.3333 m³ with 36 bags and will end up with the same result of 12 bags per cubic meter.

You may ask, if you add all three in their respective ratio from 0.3333 + 0.5 + 1 = 1.8333 cu.m which is more than 1cu.m?

This is true as materials are still in their dry state or dry volume which have not yet mixed with water. See further discussion here.

How about Class A of 9 bags? same steps as what we did in Class AA, you need to find the ratio of gravel used to come up with 9: 0.5: 1, use the shortcut method of 36 bags divide this with the given 9 bags gives you 4, which will be your ratio for gravel.

Now solving for sand of 0.5 cu. m, multiply with your gravel ratio of 4 and you get 2. To check 2/4 is equal to 0.5

To check for cement, 1/4 = 0.25 x 36 = 9 bags or

0.25/0.02777 = 9 bags

Therefore mixing ratio for your Class A Concrete is 1: 2: 4

Class B computation

36/7.5 = 4.8 round it up to 5 this is your gravel ratio, sand of 0.5 x 5 = 2.5

Therefore mixing ratio for your Class B Concrete is 1: 2.5: 5

Class C computation

36/6 = 6 this is your gravel ratio, sand of 0.5 x 6 = 3

Therefore mixing ratio for your Class C Concrete is 1: 3: 6

B. HOW TO COMPUTE for CEMENT, SAND, and GRAVEL (for estimate purposes only)

Now that you learned about the different Concrete Class Mixture with corresponding bags and cubic meter for its aggregates, plus the mixing ratio, what's next?

Refer to Table 01

Values of 12, 9, 7.5, 6 bags and 0.5cu. m, 1cu.m will be your guide in estimating the number of bags needed for cement, while cubic meters for your sand and gravel that needs to be purchased.

Sample estimate application:

Footing size of 1.20m x 1,20m x 0.35m thickness with a total of 7sets, how many bags of cement, cu. m of sand and gravel needed?

- 7sets x 0.504m³ = 3.528m³ total volume

- use Class A

|

| cement, sand, gravel estimate |

Using Class A as per Table 01 as reference with 9 bags, 0.50, 1 ratio per cubic meter.

- 9 x 3.528m³ = 32 bags

- 0.50 x 3.528m³ = 1.764m³ sand

- 1 x 3.528m³ = 3.528m³ gravel

Just note that this is an estimate only and you don't need to buy the whole number of bags based from your computations but do the purchase by 50% then gradually add another 10% as you check with your inventory from time to time.

Site factors may affect your quantity say a watery soil may require additional cement that even after "dewatering" procedure, water persist every minute which affects your mix ratio.

Size of excavated footing differs to what is drawn on paper, as actual excavation have tendency to increase in size depending on assigned manpower to do the job.

There are conditions beyond your control during actual construction so never consider your estimate as absolute.

C. FOR ACTUAL MIXING of CONCRETE on SITE

Here is where your mixing ratio of CSG is applied, say for a 1:2:4 ratio

- for every 1 bag (40kg) of cement, you need 2 boxes of sand, and 4 boxes of gravel

|

| mix ratio using measuring box |

- most contractors/home owners will skip using this method and will rely to alternatives like the use of a 16L pail from used paint container (any of these two or other brands).

|

| 16 Liters pail |

pssssst Bosyen baka naman pangalawa mo na to...

- by mathematical computation to convert cu.ft to liters, 1 cu.ft = 28.316846 liters, therefore 2cu.ft = 56.63 liters and 4cu.ft = 113.27 liters, divide both with 16 liters to get your sand and gravel measurement using your pail.

- 1:2:4 using pail is 1 bag of cement, 3.54 pails of sand, and 7 pails of gravel

|

| mix ratio using 16L pail |

Water cement ratio for any mix 0.40 to 0.60 of your 40kg cement, check if your aggregates are dry or with water content as this will affect your mix ratio.

Best to start with 10 liters then add gradually, not directly pour 16 to 20 liters without checking thoroughly your aggregates.

This is considered as "one batch" only.

HOW TO COMPUTE FOR NUMBER of BATCHES NEEDED

The next step you need to learn is to how many times will you be mixing a 1 bag of cement to a cu.m of sand and gravel into your 1 bagger mixer, which is referred as "batching".

This is important so that you can control the number of bags based from your computed quantity of CSG for every area, and not go beyond the estimated of bags & aggregates assigned for pouring of concrete at designated areas.

Say, 7 sets of footings you have computed the number of bags and aggregates needed, then 7 sets intended for your columns which requires different quantity of bags and aggregates and so on.

If you computed 36 bags for your footings then, this is also be your "number of batches required" to pour your footings, unless otherwise uncontrolled factor arise like swampy soil or watery after doing excavation which will cause some adjustments if dewatering fails.

Detailed explanation and sample computation here.

Correct Concrete Mix Ratio

Commonly used is 1:2:4 but others contests that this ratio is only 2175psi as per table below. As long as proper mix ratio and water ratio is observed with proper materials used, admix for hydration, water reducer etc, the actual compressive strength may vary.

|

| concrete grade image from leadfoxcloud.com |

Reason why during the mixing stage, slump test is conducted plus samples taken for compressive strength analysis.

- More water = weak concrete,

- Less water = less workable and may affect strength, plus expect more honeycomb to occur

The more you add ratio of aggregates to your cement, the lower strength to your concrete, the closer the ratio of aggregates to your cement the stronger your concrete, but will depend if proper water cement ratio were applied and materials used are free from dirt or oils that affects binding of cement with other aggregates.

If you happen to encounter mix ratios like 1:2:3, 1:3:3 etc and claims to to be 3000psi, as long as they conducted their own tests and approved by their own Structural Engineer, then it is up to your Engineer to decide if it is safe to use and must also conduct its own tests to back up such claims.

Disclaimer: This is not a paid promotion of any brands mentioned in this post but for sample reference only to get some idea.